Swing shear cut to length line is one kind of cut to length lines, It equips with swing shear which can swing side by side so as to cut trapezoidal blanks automatically.

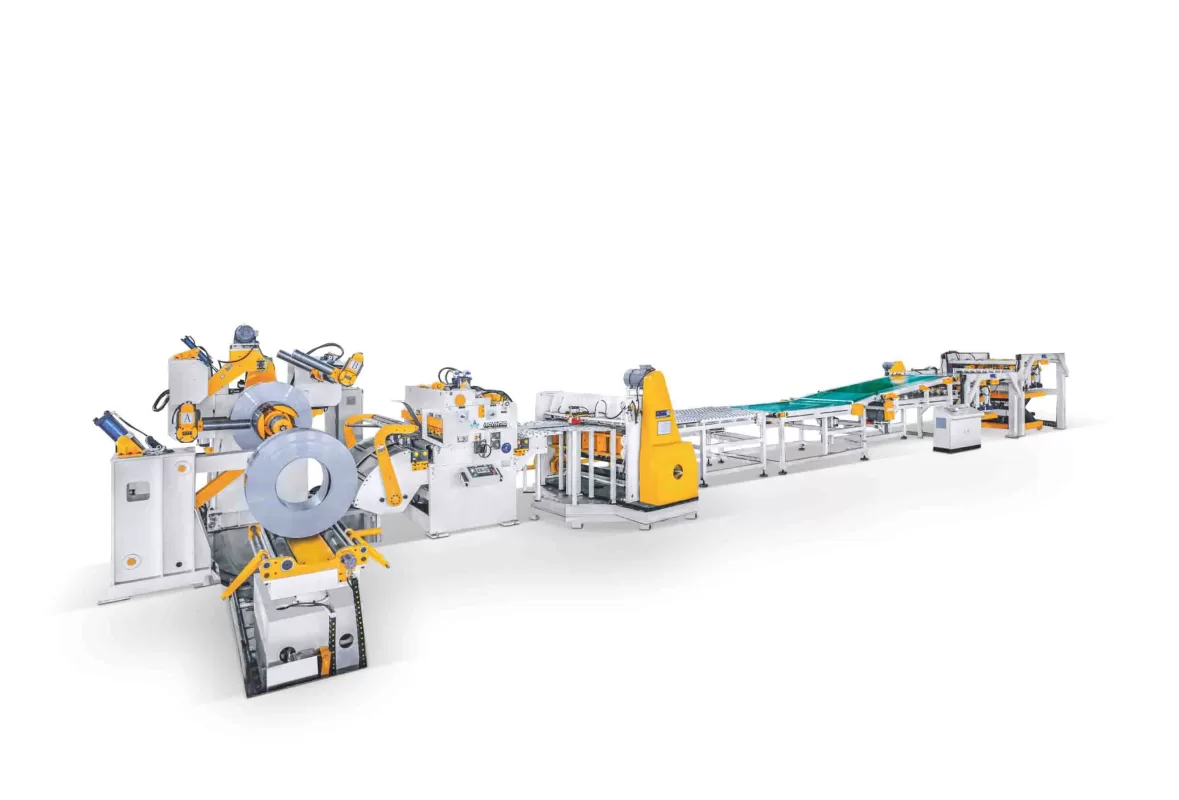

Comprising the swing shear cut to length line

- 1 set heavy decoiler with auto loading car,

- 1 set precision straightener feeder,

- 1 set swing shear,

- 1 set lift-up type conveyor belt,

- 2 sets metal sheet stacking device.

Coil was loaded, lifted and installed on decoiler’s mandrel by the auto loading car, then decoiler payoff strips and insert strip head into straightener feeder part, electric adjust straightener gap device to adjust straightening performance automatically then feed strips to swing shear after processed by straightener feeder part. Next, swing shear cut strips to required trapezoidal shape, next, the blanks were carried out by the conveyor belt and come to auto stacking system.

Advantages of the swing shear cut to length line

- Flexible and convenient to cut different angled trapezoidal blanks, just need to set swing shear’s swing angles.Space saving, setup cost saving and maintenance cost saving

It can save much

- space and foundation cost etc. than blanking by stamping press line which need deep pit for press and coil feeding line etc. It also saves much space for stamping dies storage and maintenance cost for stamping dies etc.

- Can also be used as standard cut to length line to produce rectangle metal blanks.

Main parameters of the swing shear cut to length line

| No. | Item | Main parameters | Remarks |

| 1 | Material capacity | Low carbon steel, stainless steel, high tensile steel etc. | |

| 2 | Width range | 100-1700mm | |

| 3 | Thickness capacity | 0.5-4.5mm | Can customized as buyer’s requirements |

| 4 | Max. coil weight | 12T | Can customized as buyer’s requirements |

| 5 | Coil fed speed | 1-20m/min | Can customized as buyer’s requirements |

| 6 | straightening accuracy | Less than 1.5mm per meter | |

| 7 | Swing angle range | 0°-30° | |

| 8 | Stacking height | About 500mm | |

| 9 | Product counting | YES | |

| 10 | AC voltage | 3 phase 380V 50HZ | Or local voltage |