Stamping press is a key tool in modern manufacturing. By shaping or cutting sheet metal or other materials into specific shapes, it provides precise and efficient production solutions for a variety of industries.

This article will give you an in-depth understanding of the basic principles, different types, application areas and impact of stamping press on the manufacturing industry. It will also explore the future development trends of stamping technology.

Introduction to Stamping Press

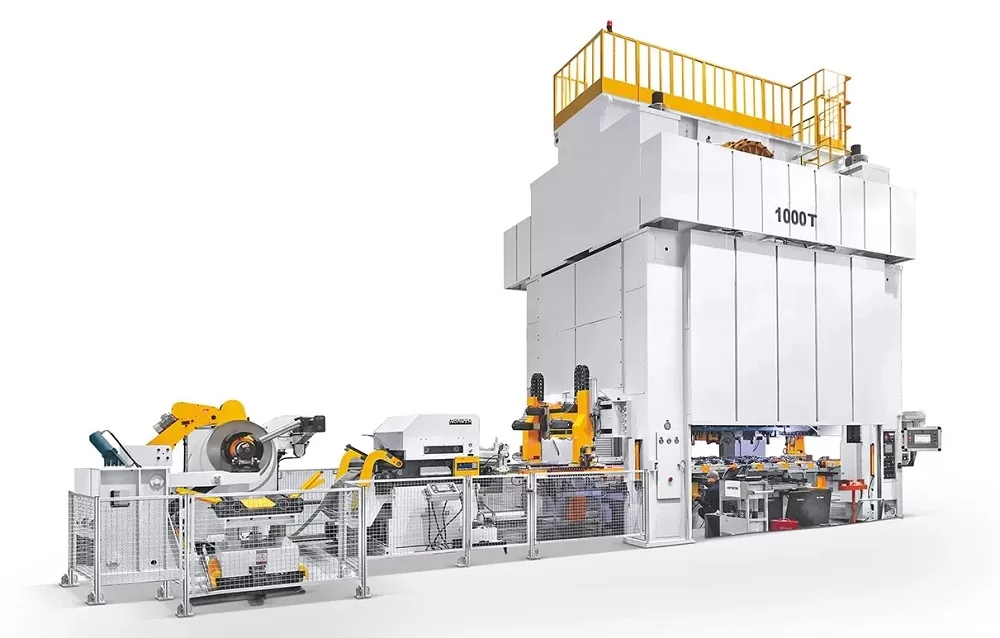

Before discussing various aspects of stamping press, let us first understand what a stamping press is. A stamping press, also known as a stamping machine or stamping press machine, is a machine used to shape or cut sheet metal or other materials in manufacturing and metalworking processes.

A stamping press machine works by placing material inside a stamping die and then applying high pressure to deform the material into the desired shape or cut it into specifically shaped parts. The operation of a stamping press is typically precise and efficient, making it ideal for mass production.

Types of Stamping Press Machines

There are two main types of stamping press machines: mechanical and hydraulic. They differ significantly in terms of operating principles, application areas and performance.

Mechanical Stamping Press

Mechanical stamping press uses mechanical power to perform the stamping operation. The machine typically consists of a crankshaft, connecting rods, and flywheels that generate high pressures through mechanical motion.

It is capable of performing stamping operations at relatively high speeds and can complete multiple stamping operations in a short period of time, making it suitable for tasks requiring high productivity. In addition, mechanical stamping machine is highly precise and can produce parts with accurate shapes and consistent dimensions, which helps ensure product quality.

Mechanical stamping machines are suitable for tasks such as cutting, punching and forming relatively simple shapes that require continuous stamping at high speeds.

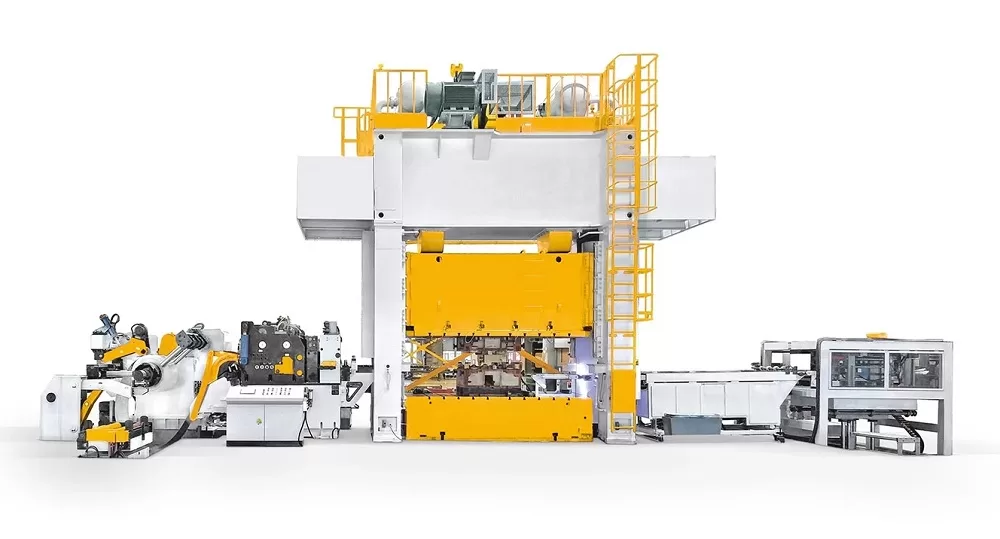

Hydraulic Stamping Press

Hydraulic stamping press uses a hydraulic system to generate pressure. Compared to mechanical stamping press, hydraulic stamping press is more suitable for applications requiring greater pressure and more complex forming. The hydraulic system provides greater control, allowing the operator to adjust the punching force and speed to meet different requirements.

It is more adaptable and can perform a variety of tasks, including punching, bending, pressure forming and deep drawing. Haiwei’s hydraulic stamping press machines excel at manufacturing large parts, performing complex forming operations, and applications requiring higher pressure and control precision.

How Does a Stamping Press Work?

Understanding how the metal stamping press machine works is essential to developing a deep understanding of its capabilities. The working process of the stamping machine includes the following steps:

Feeding: The first step in the stamping process is to feed the raw material into the stamping press machine. This typically involves loading sheet metal or roll material into the feed system of the punch press. The feed system positions the material to where it is to be stamped, ensuring the accuracy and consistency of the stamping operation.

Forming or Cutting Process: Once the raw material is accurately positioned, the stamping machine applies high pressure through the punch and die to form the material. The forming operation deforms the material into the desired shape, while the cutting operation cuts the material into specifically shaped parts. The design of the punch and die determines the shape of the final product.

In a mechanical stamping press, mechanical power pushes the punch downward, causing it to exert its force on the material. In a hydraulic stamping press, the piston of a hydraulic cylinder pushes downward, transmitting hydraulic force to the punch, thereby performing the stamping operation.

The quality and accuracy of the finished part depend on several factors, including the properties of the material, the design of the mold, and the control system of the stamping press. Stamping machines can perform a variety of operations, including punching, bending, deep drawing and pressure forming, making it versatile for a variety of tasks.

Ejection of Finished Parts: Once the stamping operation is complete, the finished part is ejected from the press, ready to enter the next manufacturing stage.

Application of Stamping Press Machines

Stamping press machines are widely used in various industries and are an integral part of modern manufacturing. Here are some examples of stamping machine applications in some major industries:

Automobile Manufacturing

The automotive manufacturing industry is one of the main application areas of stamping press machines. Stamping machines are used to manufacture body parts, doors, hoods, frames, chassis and other critical components. The high productivity and precision of stamping machines allow automakers to mass-produce vehicles and ensure the consistency of parts, thereby improving vehicle quality and safety.

Aerospace

In the aerospace industry, stamping press machines are used to manufacture aircraft casings, flying wings, engine parts and other critical components. These parts often require extremely high precision and quality standards, so the use of stamping machines in this industry is crucial. In addition, the aerospace field also requires reliable and high-pressure stamping machines and hydraulic stamping machines are widely used here.

Electrical Manufacturing and Electronics

In the electrical manufacturing and electronics industries, stamping press machines are used to make electronic housings, connectors, heat sinks, circuit board brackets and other components. These parts require precise size and appearance to ensure the reliability and performance of electronic devices. The high precision and production efficiency of stamping press machines enable electronics manufacturers to meet growing market demands.

Other Industry

Stamping press machines also play a key role in a variety of industries including construction, appliances, medical device manufacturing, metal processing, and plastic processing. Their versatility and customizability make them ideal for a variety of applications.

The Importance of Stamping Press in Manufacturing

Stamping press machines play a vital role in modern manufacturing and their importance is obvious. These machines provide efficient mass production solutions, allowing manufacturers to manufacture large quantities of parts quickly and accurately, thereby reducing costs and increasing production efficiency.

First, stamping machines are able to manufacture large quantities of parts in a short period of time, which is crucial for manufacturing, especially in areas that require mass production, such as automobile manufacturing and electronic equipment production. In these areas, market demand is huge and manufacturers need efficient tools to meet customer orders. Stamping machines can produce large quantities of parts with exceptional speed and accuracy, ensuring products are delivered on time while reducing production cycle times and costs.

Secondly, stamping machines play a crucial role in ensuring product quality and consistency. Through precise control and automated processes, metal stamping machines can avoid human errors. This helps manufacturers provide high-quality products, improve customer satisfaction, and reduce after-sales maintenance costs.

Additionally, stamping machines help reduce manufacturing costs. They can reduce production costs by reducing raw material waste and improving production efficiency. For example, metal stamping machines can achieve highly compact arrangements on materials, reducing waste and material costs. And the automated stamping process requires fewer operators, reducing labor costs.

Finally, the manufacturing flexibility of stamping presses is also part of its importance. These machines have the ability to adapt to different shapes and sizes, allowing manufacturers to easily switch between different products or projects. This flexibility is critical to respond to changes in market demand. Manufacturers can change stamping dies to make different types of parts without having to invest in completely different production lines. This enables them to quickly adapt to changes in market demand and meet the customized needs of different customers while maintaining efficient production.

Future Trends of Stamping Press

As technology continues to develop, the field of stamping press machines is also constantly evolving. Here are some future trends in stamping technology:

Automation and Digitalization

In the future, stamping press machines will become more automated and digital. As machine learning and artificial intelligence continue to advance, stamping press machines can be better adapted to different tasks and material types. Automation will further improve production efficiency and reduce human intervention. Digital technology will also provide more data and monitoring options, allowing manufacturers to track production processes in real-time and identify and correct problems in a timely manner.

Environmental Protection and Sustainability

The manufacturing industry is increasingly paying attention to sustainability and environmental issues. The stamping press of the future will be more energy-efficient, reduce waste, and optimize resource utilization to meet the requirements of sustainable manufacturing.

Advanced Materials and Complex Shapes

In the future, stamping press machines will continue to adapt to more advanced materials and more complex shapes. As materials science advances, manufacturers will face additional challenges requiring stamping press capable of handling high-strength steels, composites, and other innovative materials. In addition, the market demand for complex shapes is also increasing, so stamping machines require greater flexibility and precision to cope with these changes.

Conclusion

Stamping press machines play a vital role in the manufacturing industry. Their high efficiency, precision, and versatility make them an indispensable tool for modern manufacturing.

As technology continues to evolve, stamping machines will continue to adapt to changing needs and challenges, driving the manufacturing industry toward a more efficient, smarter and more sustainable direction.

Share This Post: